We are professional manufacturer located in Nanjing China with decades of years of history. OEM and ODM service is available with us. You are welcome to contact us for inquiry.

AS RS Industrial warehouse heavy duty automated Storage retrieval System Rack

AS/RS(automated storage and retrieval systems) refers to a variety of computer-controlled methods for automatically placing and retrieving load from specific storage locations. An AS/RS environment would encompass many of the following technologies: Horizontal Carousels, Vertical Carousels, Vertical Lift Modules (VLM) and traditional Crane-in-Aisle Storage & Retrieval systems that utilize storage retrieval (SR) crane.

Features:

1)Make full use of space for automated warehouse is an important part of storage, storage of goods by using multi-level warehouse system

2) height can reach 30 meters, according to the needs of different types of elevated can set more than 12 meters high , middle (5-12 meters), and low (5 meters below).

3) Compared with the library can save nearly 70 per cent of the area.

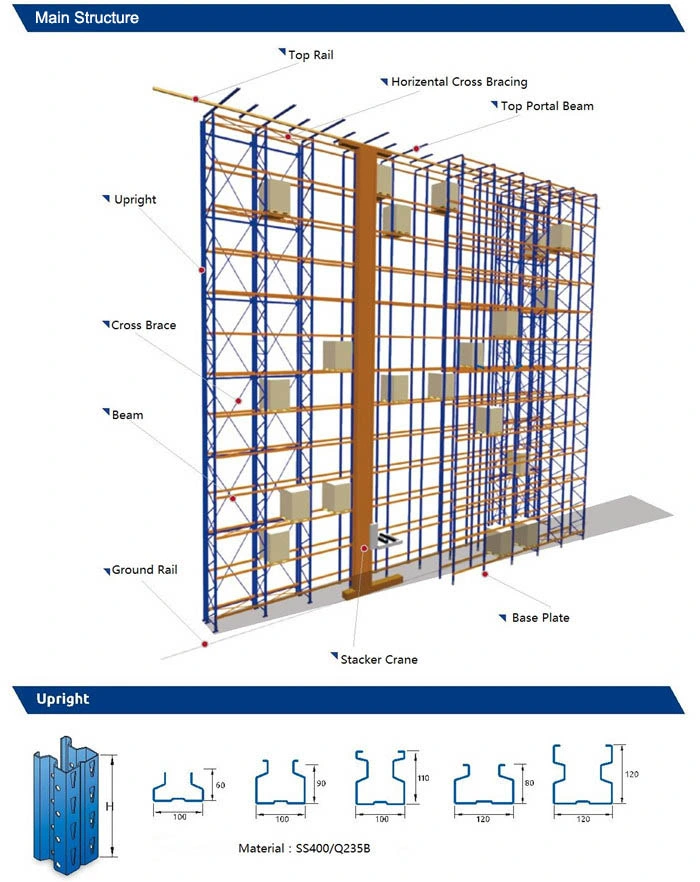

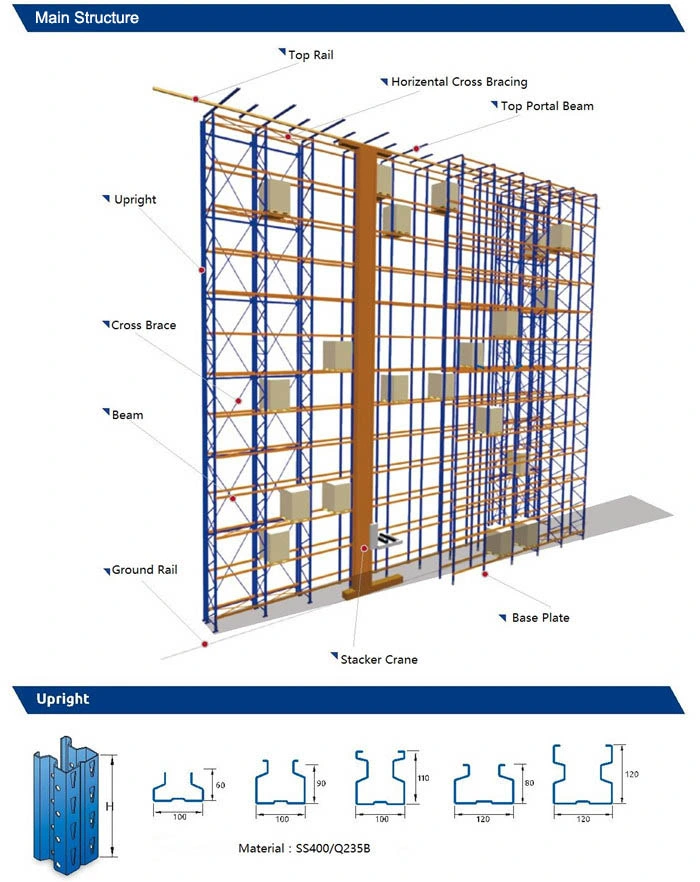

AS RS warehouse rack mainly consists of following parts:

1. Racking

Structural feature: AS/RS System are usually equipped with pallet racking and drive-in racking, both of which are composite structure. Steel panels and wooden panels are available for loading with good capacity. Conveyors will do the loading and unloading job under the instruction from the central computer. AS/RS System is mainly used in the food, tobacco, electronic, mechanical and armament industry.

2. Stacker

Structural feature: Double upright structure, steady and reliable, vector frequency conversion drive and encoder position control, mechanical and electronic safety devices to ensure safe using of the system; All the way tracing technology by information transferring; Electric components are imported from abroad; Touching screen interface for easy operation; Making manual, semiautomatic, automatic and linkage control come true; Used in many situations by combining with other logistics equipment.

3. Conveying system

Structural feature: Conveying system is usually equipped in the front or back of warehouse for conveying goods here and there, bridging the procedures done by forklifts and stackers by using rolling conveyor or chain conveyor and combining with lifts, rotating devices and other equipments.

4. Controlling system

Structural feature: Communicating with WMS and ECS through OPC agreement, PROFIBUS bus network, set up by Siemens S7-300 controller can operate all conveyors offline, doing conveying of goods automatically.

Please refer to the attached drawing for details of conveying system

5. WMS System

Hardwares of WMS System: Star network structure, network sever, RF server, computers for management and monitor, RF base station and RF terminal for in/out warehouse of goods.

Softwares of WMS System:

Operating system: WINDOW 2000X SEVER

Data-base: MS SQL SEVER 2000X

Warehouse management software: WMS

Equipment controlling software: ECS

Bar code management software: RFS

6. Other related equipment

Other related equipment include switching cart, rail cart, O/R table, automatic guided vehicle, auto-picking system, electronic label, pallet lift and so on.

Specifications:

AS RS Industrial warehouse heavy duty automated Storage retrieval System Rack

AS/RS(automated storage and retrieval systems) refers to a variety of computer-controlled methods for automatically placing and retrieving load from specific storage locations. An AS/RS environment would encompass many of the following technologies: Horizontal Carousels, Vertical Carousels, Vertical Lift Modules (VLM) and traditional Crane-in-Aisle Storage & Retrieval systems that utilize storage retrieval (SR) crane.

Features:

1)Make full use of space for automated warehouse is an important part of storage, storage of goods by using multi-level warehouse system

2) height can reach 30 meters, according to the needs of different types of elevated can set more than 12 meters high , middle (5-12 meters), and low (5 meters below).

3) Compared with the library can save nearly 70 per cent of the area.

AS RS warehouse rack mainly consists of following parts:

1. Racking

Structural feature: AS/RS System are usually equipped with pallet racking and drive-in racking, both of which are composite structure. Steel panels and wooden panels are available for loading with good capacity. Conveyors will do the loading and unloading job under the instruction from the central computer. AS/RS System is mainly used in the food, tobacco, electronic, mechanical and armament industry.

2. Stacker

Structural feature: Double upright structure, steady and reliable, vector frequency conversion drive and encoder position control, mechanical and electronic safety devices to ensure safe using of the system; All the way tracing technology by information transferring; Electric components are imported from abroad; Touching screen interface for easy operation; Making manual, semiautomatic, automatic and linkage control come true; Used in many situations by combining with other logistics equipment.

3. Conveying system

Structural feature: Conveying system is usually equipped in the front or back of warehouse for conveying goods here and there, bridging the procedures done by forklifts and stackers by using rolling conveyor or chain conveyor and combining with lifts, rotating devices and other equipments.

4. Controlling system

Structural feature: Communicating with WMS and ECS through OPC agreement, PROFIBUS bus network, set up by Siemens S7-300 controller can operate all conveyors offline, doing conveying of goods automatically.

Please refer to the attached drawing for details of conveying system

5. WMS System

Hardwares of WMS System: Star network structure, network sever, RF server, computers for management and monitor, RF base station and RF terminal for in/out warehouse of goods.

Softwares of WMS System:

Operating system: WINDOW 2000X SEVER

Data-base: MS SQL SEVER 2000X

Warehouse management software: WMS

Equipment controlling software: ECS

Bar code management software: RFS

6. Other related equipment

Other related equipment include switching cart, rail cart, O/R table, automatic guided vehicle, auto-picking system, electronic label, pallet lift and so on.

Specifications:

Model | Loading Capacity (kg) | Height | Walking Speed | Remark |

WDL-0.1T | 100 | 5-30m | 160m/min | Customized based on client' s requirements |

WDL-0.5T | 500 | 160m/min | ||

WDL-1T | 1000 | 160m/min | ||

| WDL-1.5T | 1500 | 150m/min | ||

WDL-2T | 2000 | 120m/min | ||

WDL-3T | 3000 | 100m/min |

We ensure the most productive warehouse pallet rack solution is provided whether working from your plans or developing a cost-effective layout that is just right for your needs. You are assured of the best designed, most efficient and safest racking.

We also supply accessories like collumn guard, barrier, decking panel, adjustable base plate, wire mesh plate, truck rail etc, and other material handling equipment for warehouse storage.