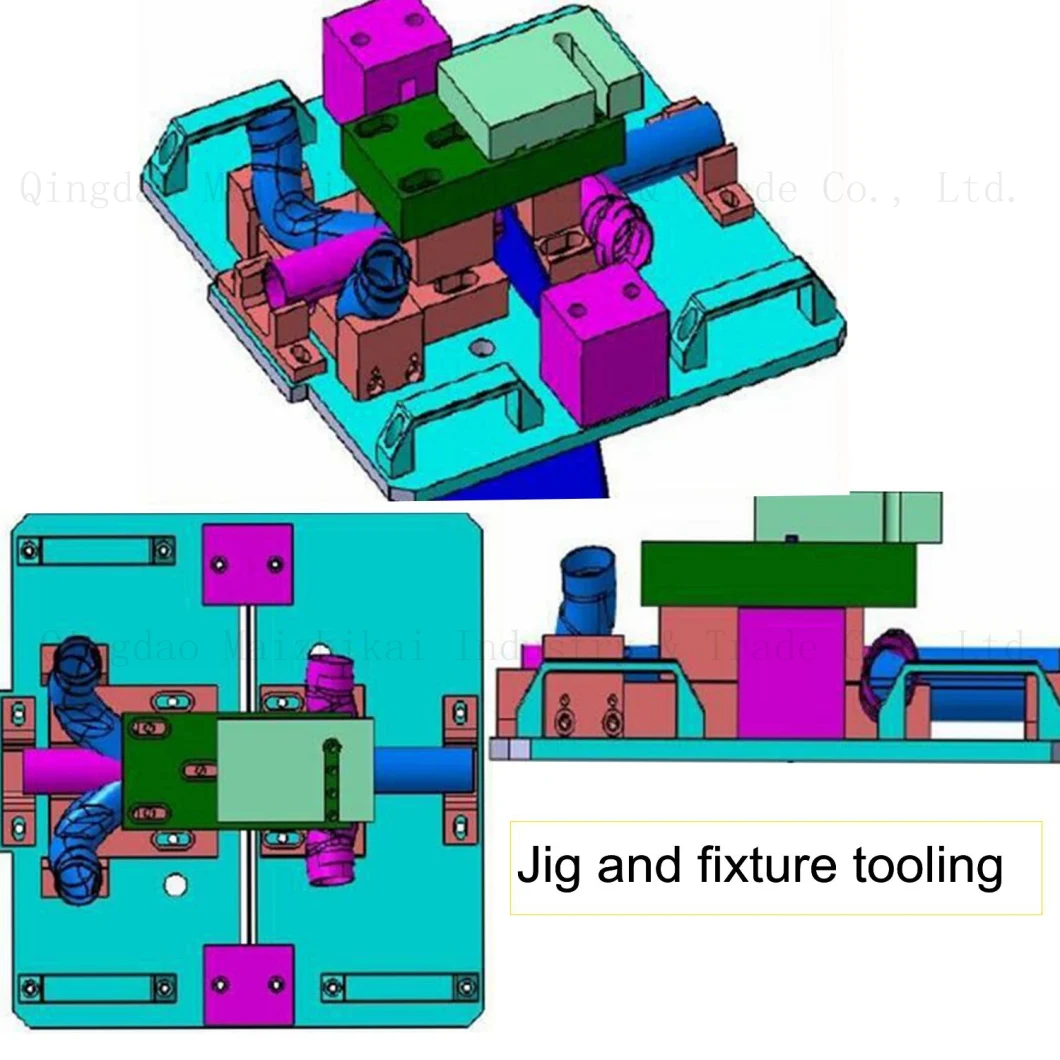

Jig and fixture tooling

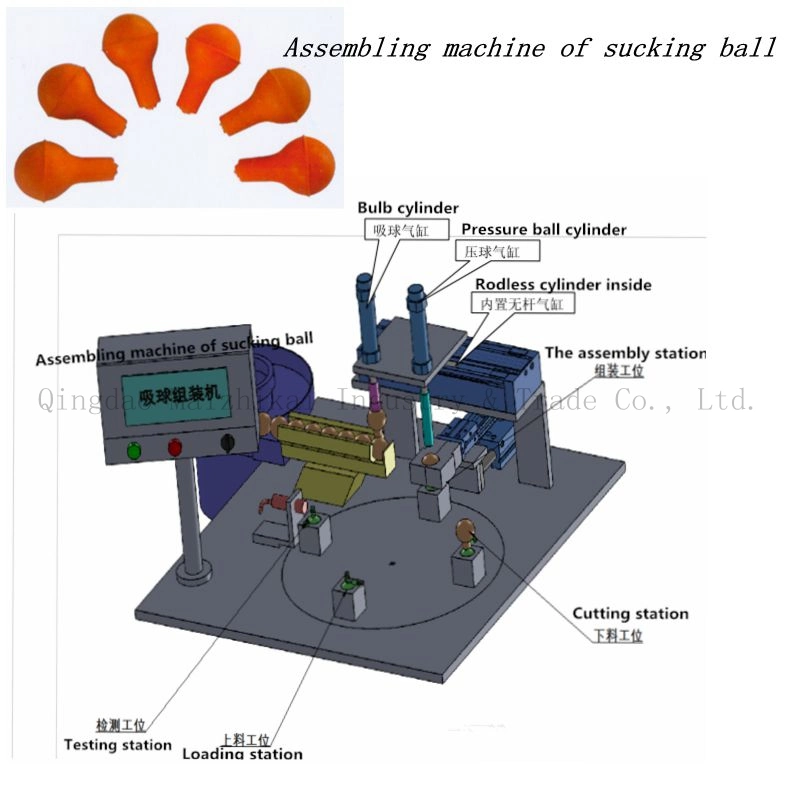

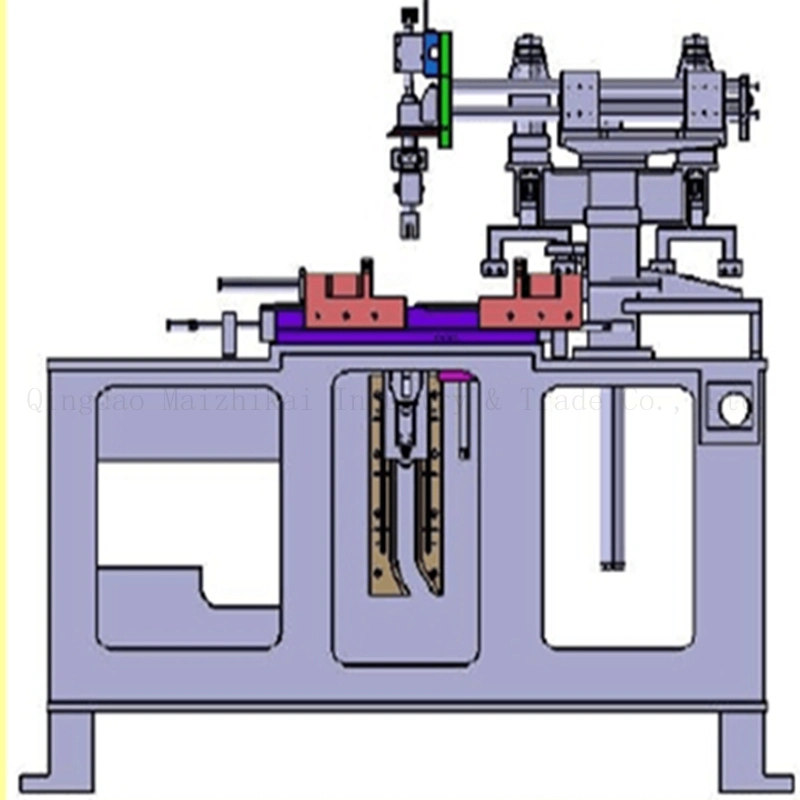

Rubber ball JIGaction specification as follows:

1. Rubber ball loadingstation have the automatic feeding device to the vibration plate , about 30pieces in one minute .

2. Rubber ball pedestal's install and remove are the manual work , the discrotation by electrical machine drive ( gear motor ) .

3. Automatic feeding device and installation accessories can be changed tomeet different customers' needs .

4.The install speed of the JIG about one piece / 4 seconds .

5.Make sure the rubber ball JIG assembly in place ,surface no any indentation and scratch .

6.Equipment whole technical parameters

1).Main frame ( no display in the picture )

A).The body made by 40*40 thickness aluminum material , elegant appearance .

B).Electrical cabinet made adopt the coldplate bending , surface by electrostatic spraying .

C) .Equipped with 4 pieces of adjustable foot , 4 piecesof brake direction wheel , whole equipment can move freely .

2). Choose the standard homebred high quality automatic feeding device to feed and can sequencingactivities , small noise , low failure frequency .

3).Pneumatic parts , all cylinderadopt Japan's SMC brand , ensure the long-time use , no breakdown happen .

4).Bottom of JIG part : Manual work loading station , testing station ,assembly station , manual work unloading station ; Taiwan geared motor : gear motor set the funcation of frequencycontrol of motor speed , speed conversion of 4 pieces' station changed byadjusting the gear motor speed .

5).Capacity : time of accomplish the assembly cycle same as 4 stations eachoperation , about 2-4 seconds .

6).Electrical device :

A).Touch screen adopt Taiwan brand - Weinview.

B).PLC adopt Japan's Mitsubishi .

C).Button to stop adopt Germany's Siemens .

D).The circuit breaker and other electrical componentsadopt brand from South Korea or Taiwan company .

7).Power supply : three-phase current 380V , 50HZ .

8). Coating color : silver-white .

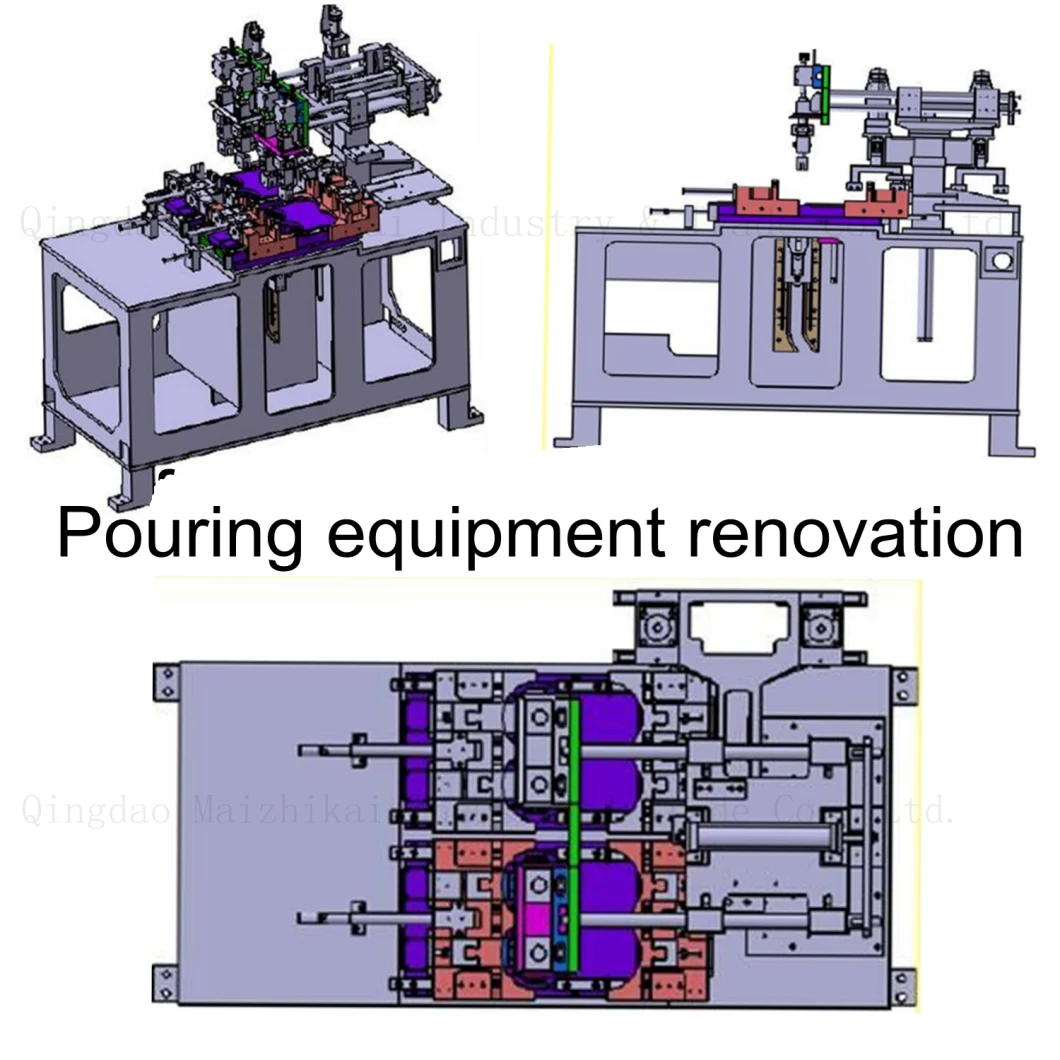

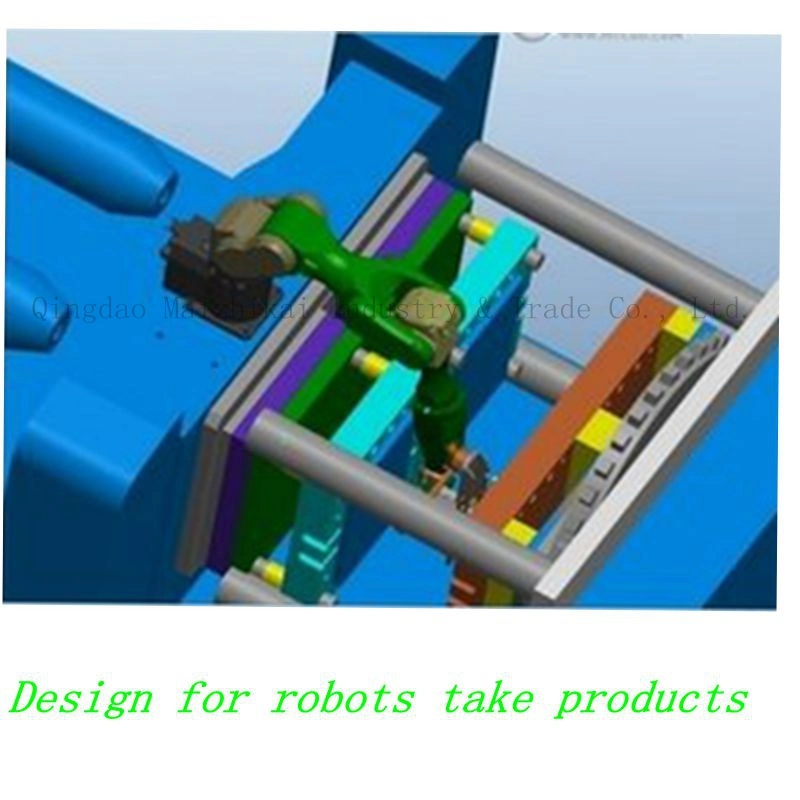

our others customized design jig and fixture tooling as follows:

Why you choose us ?

1.State-of-the art technologies

2.First-rate facilities

3.Best service ,high quality and competitive price

4.Professional team designer and Professional Jig and fixture tooling assembly team.

5.Our strength is complex high precision jig fixture

our factroy workshop photo as follows;

Introduce our company :our factroy workshop photo as follows;

Qingdao Maizhikai Industry & Trade Co., Ltd., established in 2010, is located in the beautiful coastal city of Qingdao,shangdong Province China. The company has more than 9 years of rich and unique experience in the production of various jig and fixture tooling /plastic mold/casting mold/plastic products/hardware parts and can be customized according to customer requirements and specifications.

If you have the injection mould demand pls contract us :

Weixin:sunny188299

Mobile:15192617355

Mobile:+86-15192617355

Welcome to our factory !